Lean construction

Experience building with less waste, more value

Consistent, reliable outcomes through Lean construction thinking

Cost overruns. Materials waste. Blown-out schedules. Project owners need an answer to “over budget, delivered late.” They need Lean construction—viewing projects through a lens that removes waste, reduces rework, puts the right people in the right places and drives efficiency, cost reliability and safety, from day one to job done.

Born in manufacturing, built for construction

Rooted in manufacturing principles, Lean thinking begins by scrutinizing each task and movement to find the most efficient, reliable way to work. For more than 30 years, Boldt has helped lead the industry in using that same Lean methodology in the construction process. Our proven Lean construction approach delivers less waste, consistent outcomes, reliable schedules and lower costs. That’s what it means to build boldly.

The Boldt Production System® (BPS)

Imagine predictability on every project. That’s what owners get with the Boldt Production System®, our exclusive way to plan and manage work. With an ever-improving suite of tools and practices, we plan, deliver and track projects across six key performance indicators: reliability, speed to market, safety, quality and customer and worker satisfaction. Measuring beyond the industry standard—that’s the power of Boldt.

Target Value Design (TVD)

In a traditional approach, a designer creates designs and a general contractor bids based on them. If bids are over budget, time and desired elements may be lost in the redesign process. If you don’t want to sacrifice vision to stay on budget, you need a different approach to estimating design. With Target Value Design, Boldt works with the owner and designer to establish the project budget, and then provides continuous estimating throughout design. Design will be constantly in alignment with the budget, resulting in the final project you envisioned.

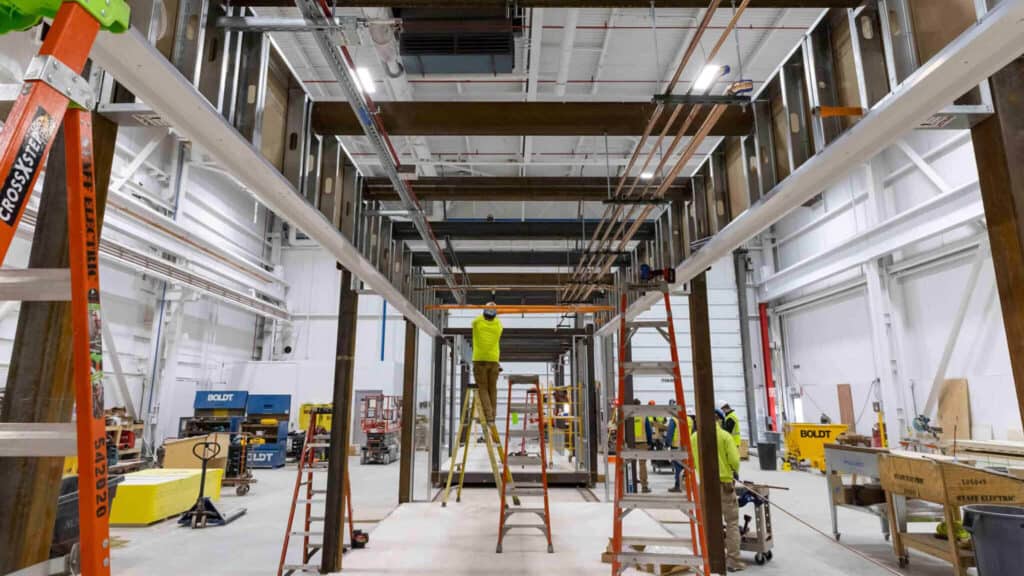

Prefabricated and Modular Construction

A natural evolution in Lean construction thinking, prefabrication and modular construction is revolutionizing how projects are delivered. By producing components, subassemblies and even entire volumetric rooms in an off-site manufacturing facility, Boldt improves jobsite safety, quality and budget predictability. Boldt is an innovator in prefabrication and modular construction. With substantial investments in manufacturing capabilities and a team of experts to customize solutions, Boldt offers our clients innovative prefabrication and modular solutions that meet their needs. Learn more about prefabrication and modular construction.

Continuous Improvement and OneBoldt

At the core of Lean thinking is learning. Embracing what works. Eliminating what doesn’t. As a Lean construction pioneer, Boldt embraces a culture of continuous improvement and “OneBoldt,” where project teams from across the country share their experiences and knowledge gained, so with each project completed, we get better, faster and safer.

Cutting-Edge Technology

To keep pace in today’s world, you need technology solutions that improve the way projects are planned, estimated, tracked and communicated—from the start. Building Information Modeling (BIM) helps partners see the project clearly, improve estimates and identify potential conflicts up-front. Scheduling in 4D and 5D creates better sequencing and phasing for improved risk management. Virtual jobsite tours engage clients in any location, while laser scanning helps verify delivery and drone flights provide complete project overviews. At Boldt, cloud-based technology is powering improved construction with owners, trade partners and crews. Learn about Boldt Virtual Design and Construction services.

Lean Construction is in our DNA

For more than 30 years, Boldt has helped lead the construction industry’s Lean revolution. As a founding member of the Lean Construction Institute, Boldt pioneered systems and practices now used industrywide. Delivering budget certainty. Creating open communication. Achieving consistent, quality results that drive efficiency and improve customer satisfaction. Today, Boldt teams apply Lean construction expertise to each and every project we deliver—while continuously working to move the industry forward.

A Lean thinking mindset, a master builder’s skillset

The ingenuity of an innovator. The preparation of a pro. That’s the Lean construction expertise Boldt brings to every project. Leading and learning, enabling your project to shine.

Shorter schedule durations

Dramatically reduced or eliminated rework and waste

More predictable, reliable project outcomes

Enhanced cost control measures

Better project understanding and communication